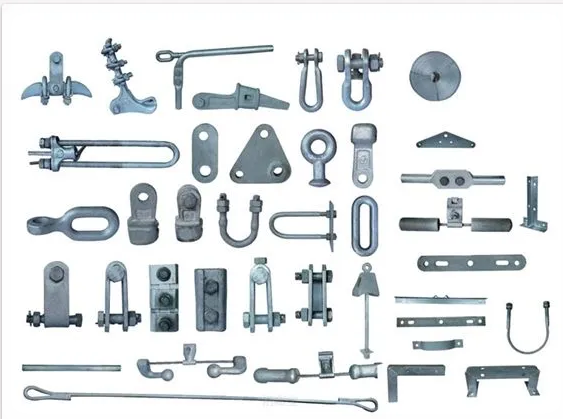

Connecting fittings are a core category of power fittings responsible for "transmission" and "connection". Their main function is to realize mechanical connection and current transmission between conductors, between conductors and equipment, and between fittings, and serve as a key link to ensure the dual stability of "current flow" and "mechanical force bearing" in power systems.

Features:

Excellent electrical conductivity: Fittings used for current transmission (such as splice sleeves and terminal clamps) must be made of high-conductivity materials (e.g., copper, aluminum). Their contact surfaces must be processed to be smooth, ensuring low contact resistance and preventing overheating and burning during operation.

Compliant anti-corrosion performance: Fittings used outdoors must undergo anti-corrosion treatment (e.g., hot-dip galvanizing, anti-corrosion paint coating). For coastal or industrial areas, stainless steel materials should be selected to prevent environmental corrosion from affecting their service life.

Reliable mechanical strength: They must be able to withstand loads such as tension, compression, and vibration of conductors. The rated breaking load must match the design load of the line to prevent line failures caused by the fracture of connection parts.

Accurate adaptability: The specifications of the fittings must fully match the conductor cross-section, the size of equipment terminal blocks, and the models of other fittings. This avoids poor contact or stress concentration caused by dimensional deviations.